Reshape the Future with Molded Fiber

Innovation, Rooted in Nature

We provide access to planet-friendly, purpose-driven products by pushing the limits of molded fiber design.

Sustainable Product Design

Luxury Packaging

Custom Food & Beverage

Levels of Engagement

Every project starts in a different place. These are the three most common ways clients begin working with Tanbark.

Manufacturing

Already have a finished molded fiber design? We’ll build the tooling and manufacture at scale — simple, reliable, and right here in the U.S.

Design

Need to adapt an existing part for molded fiber? Our design team partners with you to refine functionality, aesthetics, and manufacturability.

Innovation

Looking to push the limits of molded fiber? Our engineers and designers collaborate with you to create what’s never been done before.

Frequently Asked Questions

-

Yes, but better!

Tanbark uses Type 3 processing, also known as Thermoformed Molded Fiber, using a screened tool for the first step followed by pressing the part between matched metal tools to compress and dry the part. This process creates precise parts with finished surfaces on both sides.

Molded fiber egg cartons are made using a Type 2 molded fiber process, which forms pulp to a screened tool which is picked up by a transfer tool that then drops the part onto a drying line. Type 2 parts have one finished side and one rough side and are air dried, which results in some variability in the dimensions of the final product.

-

We use the same material used in traditional paper: pulp made from natural wood fiber. Pulpwood provides both cellulose fibers for structure and lignin that acts as a natural glue to hold it all together. Similar to paper, we add trace additives (well below FDA allowed limits) to assist with processing and moisture resistance–all of which are recyclable and break down into natural components in composting. Our typical parts are made from a blend of softwood and hardwood pulp–contrary to what the name suggests, the softwood provides strength through longer fibers while the hardwood provides excellent surface finish through shorter fibers.

-

Yes, because our molded pulp parts are made from paper they are recyclable like paper or a box. In fact, paper is one of the most recycled materials there is!

It turns out that one of the popular uses for recycled paper is making type 2 molded fiber parts. Because of the structural and cleanliness requirements for the parts we make, we use virgin wood pulp, often from certified sustainable sources. Pulp is made from “pulpwood”--the smaller diameter wood that isn’t suitable for lumber or other higher value products. Full utilization of harvested fiber is essential to the economic viability of sustainable forestry–so instead of being developed, land stays forested.

-

Our current production systems can make parts that fit within 22” x 16” x 6”. We are in an expansion mode, and will always consider adding larger format equipment for the right project.

-

Type 3 processing is best for thin walled parts between 0.02” and 0.04” (0.5-1.0mm). Design features like folding hinges or nesting parts can be leveraged to add volume or structure.

-

Many of our customers prefer the natural appearance of kraft pulp fiber. We also make white parts for a more distinguished appearance. The type 3 process allows for embossing and debossing to add text (10pt or higher is best), logos, recycling symbols, etc. Finished parts can also be marked by inkjet, laser, or with labels.

-

Our minimum order quantity is based on machine cycles, so this can vary depending on the size of the parts. Generally this could be between 10,000 and 200,000 parts, but we encourage you to contact us even if you’re an innovator in launch-mode or prototype phase.

-

Our thermoformers are scaled for lower volume production runs. Our tool sets cost about as much as a nice used car, as opposed to most molded fiber lines where the price of tooling is equivalent to a nice big house, or sometimes a mansion.

-

From design to production can vary depending on the complexity of the part and the level of innovation required. Final design to production is typically between 6 to 10 weeks.

View our levels of engagement for information on what it’s like to work with us.

-

Yes! We commonly make food contact parts using FDA approved materials and manufacturing practices.

-

Yes, molded fiber parts can be sterilized by a number of methods including autoclave, radiation, and ethylene oxide. Currently we do not produce molded fiber parts that can act as a sterile barrier–this is a goal for coated parts planned for the future. Typically sterilized molded fiber parts are sealed in a suitable flexible barrier material to maintain sterility.

-

With its relatively low cost and high sustainability, molded fiber parts are ideally suited for single use or limited use applications. Packaging is the most obvious use, but the rigidity and performance of the material makes it practical for a variety of structural or design-focused applications–for example: monocoque bodies for disposable medical devices, lamp diffusers, mold forms, desk organizers, etc. This advancement in material processing is ripe for innovative design applications. We love talking to innovative designers with bold ideas.

-

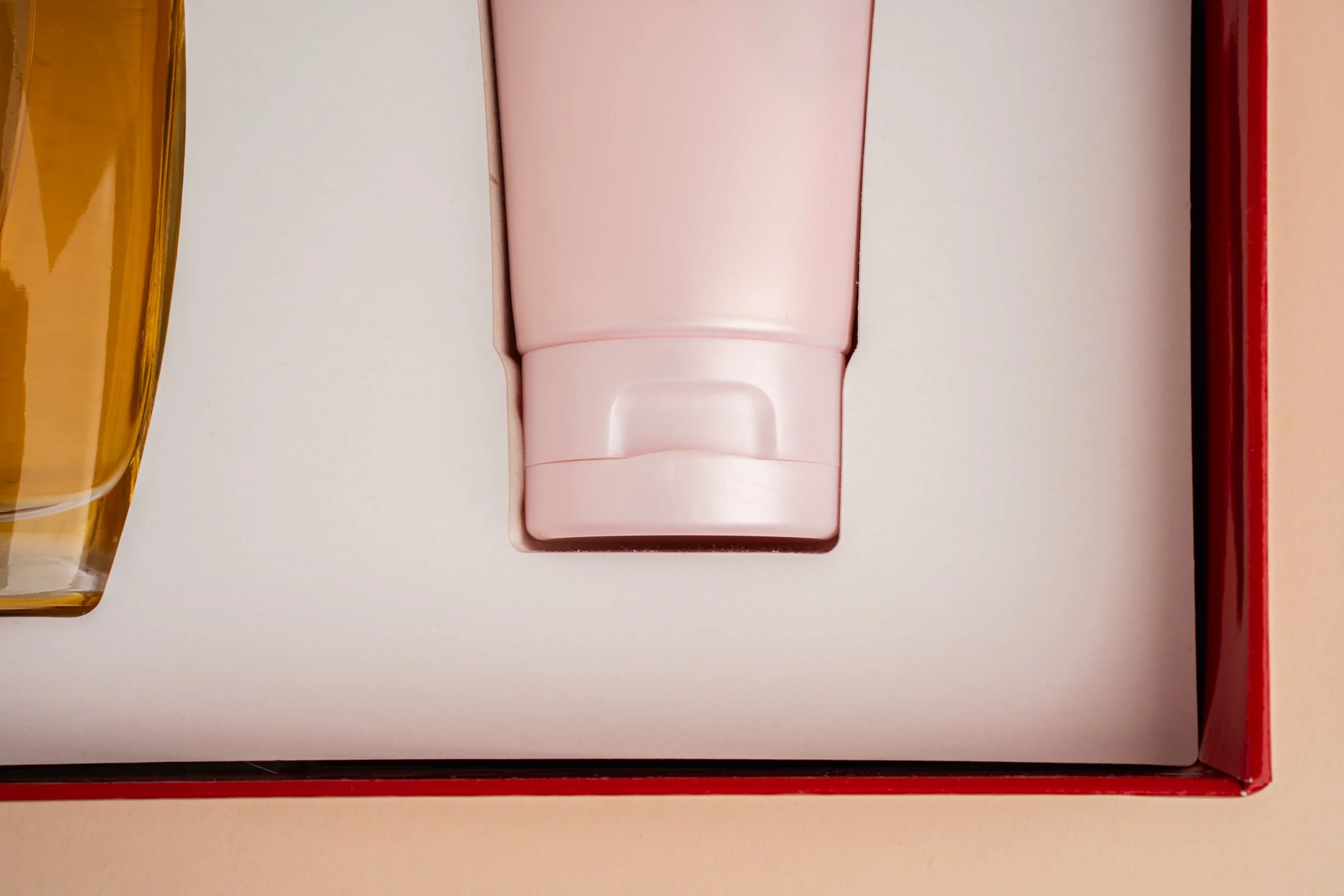

Protection, Organization, and Presentation. The precision and surface finish achieved by our process lends itself to applications where detail and appearance matter. Products can click into place; embossed logos, patterns, or text can add information and style; expertly designed geometry can provide shock absorption. A bright white molded fiber insert in beauty packaging offers an elegant presentation while protecting high-value products. A natural kraft molded part provides a visual confirmation of sustainability for earth-friendly products like organic or “clean-label” products.

-

Our products are suitable for applications like disposable food containers, or uses where there might be limited or incidental exposure to liquids or grease. Like paper, molded fiber needs to be coated in order to retain gases or stand up to extended exposure to moisture. For extended life applications like retail packaging, molded fiber is ideal for dry, shelf-stable products.

-

NO! We have never used and will never use PFAS in our molded pulp blends. (Unfortunately due to the pervasive nature of PFAS, technically anyone using natural products today has to qualify this statement by saying, no intentionally added PFAS.)

-

Trees-yes, forests-no. Forestry is analogous to farming, only far less intensive and with decades-long crop cycles. In the Northeast, forestry typically relies on natural regeneration, so harvesting activities necessarily preserve the forest ecosystem so the land will continue to produce harvests in perpetuity. Harvesting is more like a haircut than a shave–actually like a fancy layered cut. FSC Certified fiber comes from forests that are certified as sustainably managed by the Forest Stewardship Council. Tanbark is certified for chain of custody for FSC fiber and is happy to supply this for your project.

-

Working forests are managed for continued, sustainable production of forest products. Sustainable forestry aims to reach the ideal maximum repeatable annual harvest– accomplished by maximizing the forest biomass, which also maximizes the stored carbon in the forest. Unmanaged forests store carbon as well, but at much lower levels. Furthermore, much of what’s harvested from managed forests becomes durable products where carbon is sequestered for long periods of time.

-

Molded fiber is made from natural, renewable materials that break down into organic material. Plastics are made from petroleum and break down into microplastics that persist in the environment for hundreds if not thousands of years, and which tend to concentrate in living organisms, including in the vital organs of humans, like the lungs, liver, and brain.

As the knowledge about the problem of microplastics becomes more widespread, consumers and the brands that serve them are looking for opportunities to reduce or eliminate unnecessary plastic and use safe, natural alternatives. When you design your product or packaging using natural and sustainable molded fiber, you demonstrate to your customers that you care about them, their children, and the planet.